JKZ Company Profile

Understanding the fundamentals of solids control in drilling operations

Introduction Content

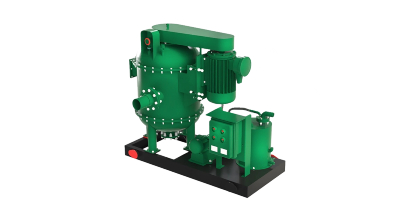

Before step into development and manufacturing of solids control and drilling fluids separation systems and technical solutions, we have been specializing and experiencing in metal fabrication and machining service industries for more than 15 years. Serve to those prestigious and reputable domestic enterprises with high quality and rigorous standards in energy, aerospace, eco-friendly protection industries, we were growing rapidly and making great improvement in production process, efficiency and quality control test and inspection. Compare with offers from other companies in solids control fields, we ensure our offers are more competitive and cost-effective while the quality and performance of our products are reliable and consistent.

Our capability of metal fabrication and drilling fluids related equipment manufacturing services has acquired highly praised and recognition along with experiences of cooperation with BOMCO, Kerui, Jereh those world reputable companies in oil & gas exploration industries and STEC, CRCC these national infrastructure contractors.

Learn More