Advanced Mud Gas Separation Technology in Solids Control Systems

In the complex world of drilling operations, the presence of formation gases in drilling fluids presents significant safety challenges and operational inefficiencies. JKZ's advanced mud gas separation technology is engineered to address these challenges head-on, providing superior gas removal capabilities while maintaining optimal drilling fluid properties.

Our innovative approach to gas separation combines cutting-edge engineering with practical field experience, resulting in systems that not only enhance safety but also improve overall drilling efficiency and reduce environmental impact.

"Effective gas separation isn't just about safety—it's about maintaining drilling fluid integrity and maximizing operational efficiency in challenging drilling environments."

- Dr. Michael Chen, Senior Drilling Engineer at JKZ

The Critical Importance of Mud Gas Separation

Gas-cut drilling mud can lead to numerous operational challenges and safety hazards:

Safety Risks

Flammable gases pose explosion hazards and health risks to personnel

Reduced Efficiency

Gas-cut mud reduces hydrostatic pressure and drilling efficiency

Fluid Properties

Gas contamination alters critical drilling fluid properties

Well Control Issues

Inadequate gas separation can lead to well control challenges

JKZ's Advanced Gas Separation Technology

Our comprehensive gas separation solution integrates multiple technologies to create a robust system that effectively removes entrained gases from drilling fluids:

Performance Specifications

Integrated System Components for Optimal Gas Separation

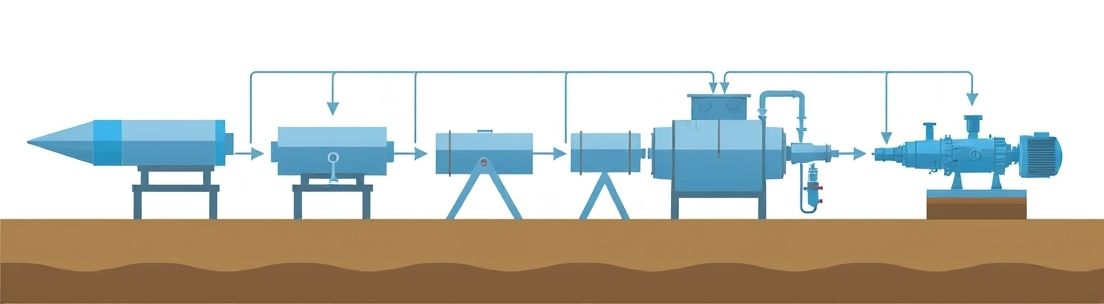

JKZ's mud gas separation system incorporates multiple stages of treatment, each designed to maximize efficiency and safety:

- Primary Separation Vessel Safety: Large-volume chamber for initial gas breakout and separation

- Defoaming System: Advanced chemical injection for foam reduction and prevention

- Vacuum Degasser Safety: High-efficiency removal of dissolved gases from drilling fluid

- Atmospheric Degasser: Secondary treatment for residual gas removal

- Gas Venting System: Safe diversion of separated gases away from the rig area

- Monitoring & Control Safety: Real-time sensors and automated control systems

Comparison: Conventional vs. Advanced Separation Systems

The following table highlights the advantages of JKZ's advanced systems compared to conventional approaches:

| Parameter | Conventional Systems | JKZ Advanced Systems |

|---|---|---|

| Gas Removal Efficiency | 70-80% | 95-98% |

| Foam Handling Capability | Limited | Advanced defoaming |

| H₂S Resistance | Basic | Full protection |

| Automation Level | Manual operation | Fully automated |

| Safety Features | Standard | Enhanced protection |

| Maintenance Requirements | High | Low |

| Environmental Compliance | Basic | Full compliance |

Advanced Technologies for Superior Gas Separation

JKZ incorporates several innovative technologies to enhance the performance of our mud gas separation systems:

Multi-Stage Separation

Combination of gravitational, centrifugal, and vacuum separation methods

Smart Monitoring

IoT sensors and AI algorithms that optimize performance in real-time

Enhanced Safety Systems

Explosion-proof components and emergency shutdown systems

Closed-Loop Design

Minimizes atmospheric release of separated gases

Safety Compliance and Certification

JKZ's mud gas separation systems are designed to meet and exceed international safety standards:

"Safety is our highest priority. Our gas separation systems incorporate multiple layers of protection to ensure the wellbeing of personnel and equipment in the most challenging drilling environments." - Sarah Johnson, Safety Compliance Director

Our systems comply with:

- API (American Petroleum Institute) safety standards

- OSHA (Occupational Safety and Health Administration) requirements

- ISO 9001 Quality Management Systems

- ATEX directives for explosive atmospheres

- Regional safety regulations across all operating areas

Case Study: Deepwater Gas Separation Success

JKZ recently implemented an advanced mud gas separation system on a deepwater drilling platform in the Gulf of Mexico, achieving exceptional results:

Gas Removal

97.5% efficiency in gas removal from drilling fluid

Safety Improvement

Zero gas-related safety incidents during operation

Operational Efficiency

22% improvement in drilling rate due to consistent fluid properties

Environmental Compliance

100% compliance with strict offshore environmental regulations

Custom Solutions for Different Drilling Environments

JKZ designs specialized gas separation systems for various drilling environments and challenges:

Future Developments in Gas Separation Technology

Looking ahead, JKZ is investing in next-generation technologies to further enhance the performance of our mud gas separation systems:

- Nanotechnology Applications: Advanced materials for improved gas separation efficiency

- Predictive Analytics: AI-driven systems that anticipate gas influx events before they occur

- Enhanced Automation: Fully autonomous systems that require minimal human intervention

- Green Technology: Systems that capture and utilize separated gases rather than flaring

- Modular Design: Scalable systems that can be easily adapted to different rig sizes and configurations

Enhance Your Drilling Safety and Efficiency

Contact our technical solutions team to learn how JKZ's advanced mud gas separation technology can improve safety and performance in your drilling operations.

Request Technical ConsultationConclusion: Safety Through Advanced Technology

Effective mud gas separation is not just a regulatory requirement—it's a critical component of safe and efficient drilling operations. JKZ's advanced separation technology represents the cutting edge of this essential field, combining robust engineering with intelligent systems to protect personnel, equipment, and the environment.

By implementing these advanced systems, drilling operators can significantly reduce risks, improve operational efficiency, and demonstrate their commitment to the highest standards of safety and environmental stewardship.