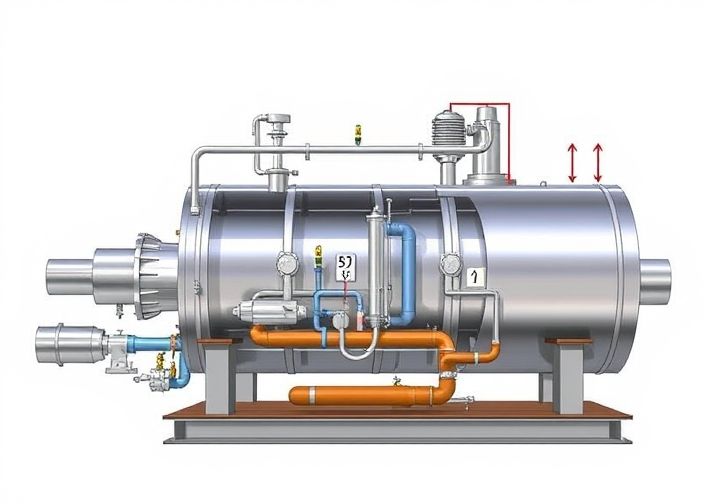

Degasser Equipment

Essential gas removal system for maintaining drilling fluid properties and rig safety

What is a Degasser?

A degasser is a critical component in solids control systems that removes entrained gases (such as methane, hydrogen sulfide, and carbon dioxide) from drilling fluids. These gases can compromise drilling fluid properties, reduce drilling efficiency, and create hazardous conditions on the rig.

JKZ degassers utilize vacuum technology to efficiently extract gases from drilling fluids, maintaining optimal mud weight and viscosity while improving safety. Our units are available in various capacities to match different rig requirements and drilling conditions.

Gas Removal

Effectively removes hazardous gases from drilling fluids

High Efficiency

Processes up to 2000 GPM with 95%+ gas removal efficiency

Safety Enhancement

Reduces explosion risks and protects personnel from toxic gases

Robust Design

Corrosion-resistant construction for harsh drilling environments