Complete Solids Control Solutions

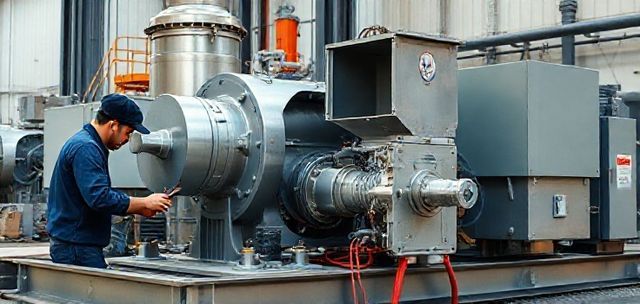

JKZ solids control systems are engineered to efficiently remove drilled solids from drilling fluids, maintaining optimal mud properties and reducing overall drilling costs. Our systems are designed for reliability, efficiency, and ease of operation in the most challenging drilling environments.

From shale shakers to centrifuges, each component in our systems is carefully selected and integrated to work seamlessly together, providing a complete solution for drilling fluid management.

Our systems are customizable to meet specific project requirements, whether for land drilling, offshore platforms, or specialized drilling operations.