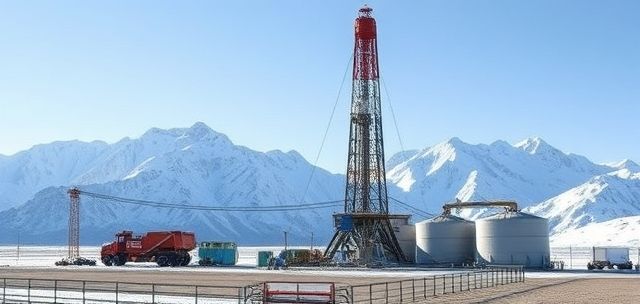

Thermal Management for Drilling Fluids

JKZ insulated solids control systems are engineered to maintain optimal drilling fluid temperature in extreme environments. These systems prevent freezing in cold climates and minimize heat loss in deepwater operations, ensuring consistent drilling fluid performance.

Our insulated systems feature advanced thermal barrier technology, integrated heating elements, and temperature monitoring systems to maintain precise temperature control throughout the solids control process.

Designed for arctic operations, high-altitude drilling, and deepwater applications, JKZ insulated systems ensure reliable performance when conventional systems would fail due to temperature extremes.