Advanced solids control solution for ultra-fine particle separation and drilling fluid conditioning

A decanter centrifuge is a high-speed rotating machine that uses centrifugal force to separate solids from liquids in drilling fluids. It's the final and most precise stage in the solids control process, capable of removing particles as small as 2-7 microns.

JKZ centrifuges are designed with robust construction and advanced features to handle the most demanding drilling applications.

Effectively removes particles in the 2-7 micron range

Generates up to 3000×g for superior separation

Adjustable bowl and conveyor speeds

Maintains ideal mud weight and viscosity

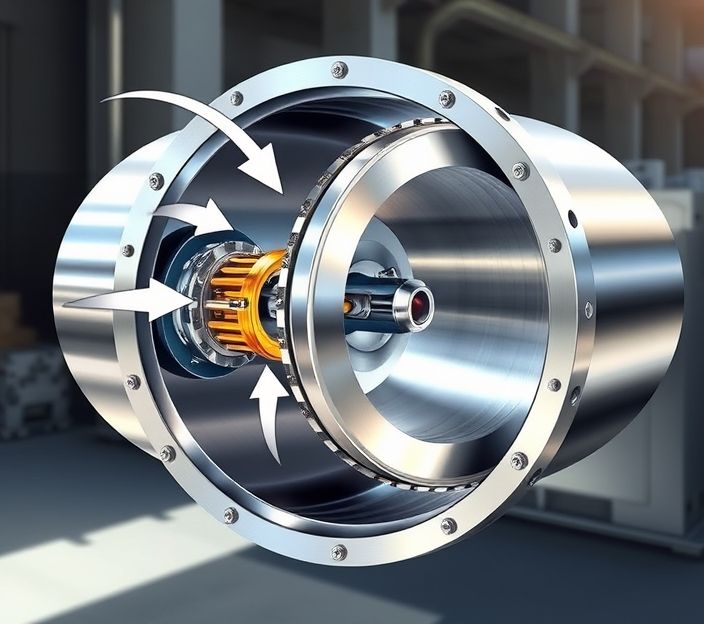

How decanter centrifuges separate solids and liquids in drilling fluids

JKZ decanter centrifuges utilize high-speed rotation to create powerful centrifugal forces that separate solids from liquids based on density differences.

Drilling fluid is pumped into the rotating bowl through a stationary feed tube.

The fluid accelerates to bowl speed, creating a liquid pool where centrifugal forces separate solids from liquid.

A helical conveyor moves separated solids toward the discharge ports.

Cleaned liquid flows over weirs while dewatered solids discharge from the other end.

Our range of high-performance centrifuge equipment

Versatile solutions for various drilling operations

Maintain optimal drilling fluid properties in oil & gas operations.

Recover valuable weighting materials and reduce waste.

Horizontal directional drilling fluid management.

Environmental dewatering for safe disposal.

High-temperature drilling fluid conditioning.

Reuse drilling fluids by removing colloidal solids.

Superior performance and reliability

Optimized design for 2-7 micron removal.

Wear-resistant materials for long life.

Adjustable parameters for any condition.

Space-saving footprints available.

Quick access and modular design.

Built to API & ISO standards.

Detailed specs of our standard centrifuge models

| Model | LW350 | LW450 | LW550 | LW650 |

|---|---|---|---|---|

| Bowl Diameter | 350 mm | 450 mm | 550 mm | 650 mm |

| Capacity | 40-60 m³/h | 60-80 m³/h | 80-120 m³/h | 100-150 m³/h |

| Cut Point | 5-7 μm | 4-6 μm | 2-5 μm | 2-4 μm |

| G-Force | 1800×g | 2200×g | 3000×g | 3200×g |

| Main Motor | 37 kW | 45 kW | 55 kW | 75 kW |

| Weight | 2 800 kg | 3 500 kg | 4 500 kg | 5 500 kg |

Contact JKZ today for expert recommendations and a tailored quotation.