Daily Inspection

Check for loose bolts, damaged screens, and proper motor operation. Inspect rubber isolators for wear and ensure all safety guards are in place. Monitor vibration patterns for any abnormalities.

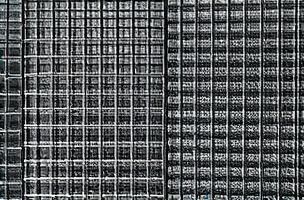

Screen Replacement

Replace screens when tears or excessive wear are observed. Always use manufacturer-recommended screens and follow proper tensioning procedures. Keep spare screens on hand to minimize downtime.

Motor Maintenance

Check oil levels in vibration motors according to manufacturer specifications. Look for oil leaks and ensure breather vents are clear. Monitor motor temperature during operation.

Lubrication

Lubricate all moving parts according to the maintenance schedule. Use only recommended lubricants and follow proper greasing procedures. Pay special attention to bearings and pivot points.

Structural Inspection

Regularly inspect the shaker bed, skid, and support structure for cracks or fatigue. Check all welds and reinforce if necessary. Ensure proper alignment of all components.

Cleaning & Storage

Thoroughly clean the shaker when changing fluid systems or before storage. Remove all drilling fluid residue and protect bare metal surfaces. Store in a dry location with screens removed.