Hydrocyclone Desander Efficiency Improvements in Solids Control Systems

Hydrocyclone desanders play a critical role in solids control systems, removing abrasive sand-sized particles (typically 45-74 microns) from drilling fluids. Recent technological advancements have significantly improved the efficiency and performance of these essential components.

JKZ's engineering team has developed innovative enhancements to traditional hydrocyclone technology, resulting in desanders that deliver superior separation efficiency, reduced maintenance requirements, and extended operational lifespan.

"Our redesigned hydrocyclone geometry and advanced materials have increased separation efficiency by up to 22% while reducing energy consumption by 18% compared to conventional desanders."

- Dr. Li Wei, Head of R&D at JKZ

Key Design Improvements

JKZ's efficiency-focused improvements target several critical aspects of hydrocyclone desander design:

Optimized Geometry

Computational fluid dynamics (CFD) analysis has enabled precise optimization of cyclone dimensions and angles

Advanced Materials

Polyurethane and ceramic linings provide exceptional wear resistance in high-abrasion environments

Precision Manufacturing

CNC machining ensures consistent dimensional accuracy across all components

Reduced Energy Consumption

Improved hydraulic design requires lower inlet pressure for equivalent separation performance

JKZ High-Efficiency Desander Specifications

Performance Comparison: Traditional vs. Enhanced Desanders

The following table illustrates the performance improvements achieved with JKZ's enhanced hydrocyclone desanders:

| Performance Metric | Traditional Desander | JKZ Enhanced Desander | Improvement |

|---|---|---|---|

| Separation Efficiency | 78-85% | 92-97% | +15% average |

| Energy Consumption | 0.45 kW/m³ | 0.37 kW/m³ | -18% |

| Wear Part Lifespan | 600-800 hours | 1000-1200 hours | +50% |

| Flow Capacity | Base rating | +15% at same pressure | +15% |

| Maintenance Time | 2.5 hours/month | 1.2 hours/month | -52% |

| Noise Level | 84 dB | 78 dB | -6 dB |

Technical Innovations

JKZ's research and development team has implemented several groundbreaking innovations in hydrocyclone technology:

1. Advanced Cyclone Geometry

Using computational fluid dynamics, we've optimized the cone angle, vortex finder dimensions, and spigot diameter to create a more stable vortex with reduced turbulence and energy loss.

2. Multi-Material Construction

Different sections of the hydrocyclone now utilize materials specifically chosen for their properties in each area of operation, combining wear resistance with impact strength.

3. Precision Manufacturing

Computer-controlled machining ensures dimensional accuracy within 0.1mm, critical for maintaining consistent separation performance across all units in a system.

Chart: JKZ Enhanced Desander shows significantly improved efficiency

across all particle sizes compared to traditional models

Operational Benefits

The efficiency improvements in JKZ's hydrocyclone desanders translate to significant operational advantages:

- Extended Equipment Life: Reduced abrasive wear on downstream equipment including pumps, centrifuges, and mud conditioning systems

- Reduced Drilling Fluid Costs: Improved solids removal efficiency decreases the need for dilution and chemical treatments

- Lower Power Consumption: Optimized hydraulic design requires less energy to achieve superior separation

- Decreased Maintenance: Longer service intervals and easier component replacement reduce downtime

- Enhanced Drilling Performance: Cleaner drilling fluid improves rate of penetration and overall drilling efficiency

Case Study: Field Performance Data

Implementation of JKZ's enhanced hydrocyclone desanders on drilling operations in the Middle East demonstrated remarkable results:

$142,000 Saved

In drilling fluid costs over a 120-day drilling program

22% Reduction

In power consumption for solids control equipment

57% Less

Time spent on maintenance and component replacement

18% Improvement

In overall drilling efficiency due to better fluid properties

"The JKZ enhanced desanders have transformed our solids control efficiency. We're seeing significantly longer equipment life and substantially lower fluid costs without compromising on separation performance." - Mohammed Al-Farsi, Drilling Superintendent

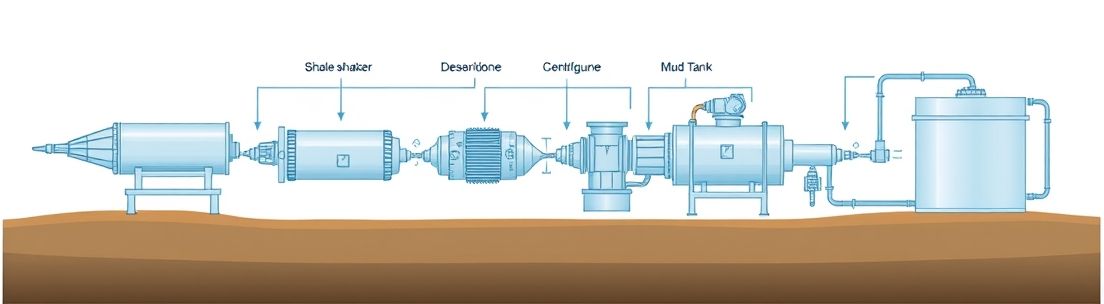

Integration with Complete Solids Control Systems

JKZ's hydrocyclone desanders are designed to work seamlessly within complete solids control systems, including:

- Shale shakers for primary solids removal

- Desilters for fine particle separation

- Centrifuges for ultra-fine solids and barite recovery

- Degassers for entrained gas removal

- Complete mud tank systems with optimized flow dynamics

Upgrade Your Solids Control Efficiency

Contact our technical specialists to learn how JKZ's enhanced hydrocyclone desanders can improve your drilling fluid management and reduce operational costs.

Request a Technical ConsultationFuture Development Directions

JKZ continues to invest in research and development to further advance hydrocyclone technology:

- Smart Monitoring Systems: Integrated sensors for real-time performance monitoring and predictive maintenance

- Adaptive Geometry: Adjustable components that can optimize performance for changing drilling conditions

- Advanced Materials: Nanocomposite materials for even greater wear resistance and lighter weight

- Energy Recovery Systems: Technologies to capture and reuse energy from the fluid stream

- Enhanced Integration: Improved compatibility with automated drilling fluid management systems

These ongoing developments ensure that JKZ will continue to provide industry-leading solids control solutions for the evolving demands of modern drilling operations.