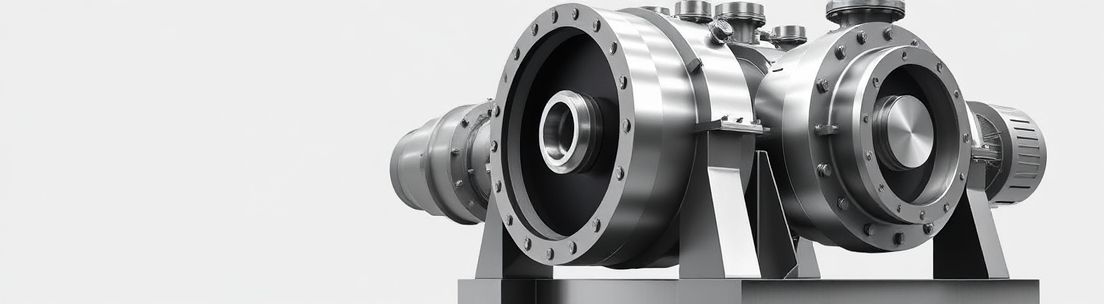

Complete Guide to Centrifuge Maintenance for Optimal Solids Control Performance

Proper maintenance of centrifuges is crucial for ensuring efficient solids control in drilling operations. At JKZ Solids Control, we've developed this comprehensive guide to help operators maximize equipment lifespan and maintain peak performance of our solids control equipment.

Regular maintenance not only extends the service life of your centrifuge but also improves separation efficiency, reduces downtime, and lowers operational costs. This guide covers essential maintenance procedures for JKZ's range of industrial centrifuges used in oilfield solids control applications.

"Preventive maintenance is the most cost-effective strategy for centrifuge operation. Regular care can reduce repair costs by up to 50% and extend equipment life by several years."

- Wang Li, Maintenance Specialist at JKZ Solids Control

Daily Maintenance Checklist

Daily inspection and maintenance are essential for identifying potential issues before they become major problems. Follow this checklist at the beginning of each shift:

Visual Inspection

Check for leaks, unusual vibrations, and abnormal noises. Inspect belts for wear and proper tension.

Lubrication Check

Verify proper oil levels and check for contamination. Monitor bearing temperatures during operation.

Electrical Components

Inspect motors, connections, and control systems for signs of damage or overheating.

Bowl and Conveyor

Check for proper operation and listen for unusual sounds that might indicate internal issues.

Safety First

Always lock out and tag out the centrifuge before performing any maintenance. Ensure the machine has completely stopped before inspection or servicing.

Weekly Maintenance Procedures

Weekly maintenance tasks help prevent the accumulation of wear and identify issues that may not be apparent during daily checks:

- Thoroughly clean the bowl, conveyor, and discharge ports

- Check and tighten all bolts and fasteners

- Inspect wear parts including the conveyor, skimmer blades, and feed zone

- Verify proper alignment of the main frame and sub-assemblies

- Test safety systems and emergency stop functions

Monthly Maintenance Schedule

Monthly maintenance involves more detailed inspections and component replacements:

| Component | Inspection | Action Required |

|---|---|---|

| Main Bearings | Check for noise, vibration, and temperature | Lubricate or replace if necessary |

| Gearbox | Oil level and quality check | Change oil if contaminated or after recommended hours |

| Drive Belts | Tension and wear inspection | Adjust or replace if worn or damaged |

| Vibration Sensors | Functionality test | Calibrate or replace if faulty |

| Electrical Connections | Tightness and corrosion check | Clean and tighten all connections |

Common Issues and Troubleshooting

Even with proper maintenance, centrifuges can develop issues. Here are some common problems and their solutions:

Excessive Vibration

Often caused by imbalance, worn bearings, or material buildup. Stop immediately and inspect internally.

Reduced Performance

Check feed rate, pond depth settings, and wear parts. Verify proper system components integration.

Overheating

Usually related to bearing issues, inadequate lubrication, or overloading. Check oil levels and quality.

Failure to Start

Check electrical connections, motor condition, and safety interlocks. Verify power supply.

Lubrication Guidelines

Proper lubrication is critical for centrifuge longevity. Follow these guidelines:

- Use only recommended lubricants specified in the operator's manual

- Follow the prescribed lubrication intervals based on operating hours

- Monitor oil quality regularly and change if contamination is detected

- Keep accurate records of all lubrication activities

- Never mix different types or brands of lubricants

Seasonal Maintenance Considerations

Environmental conditions can affect centrifuge performance. Consider these seasonal factors:

Cold Weather Operation

In freezing conditions, take extra precautions to prevent damage:

- Use winter-grade lubricants with lower viscosity

- Allow the centrifuge to warm up gradually before full operation

- Protect external components from ice accumulation

- Drain systems if equipment will be idle in freezing temperatures

Hot Weather Operation

High temperatures present different challenges:

- Monitor bearing temperatures more frequently

- Ensure adequate ventilation around the centrifuge

- Check oil cooling systems regularly

- Consider more frequent oil changes in extreme heat

Spare Parts Inventory

Maintaining an appropriate spare parts inventory minimizes downtime. Essential spare parts include:

- Bearings and seals

- Drive belts

- Wear parts (conveyor, skimmer blades)

- Gaskets and O-rings

- Electrical components (fuses, sensors)

JKZ offers genuine replacement parts designed specifically for our centrifuge models, ensuring optimal performance and compatibility.

Training and Documentation

Proper training is essential for effective maintenance. JKZ offers:

- On-site operator training programs

- Detailed operation and maintenance manuals

- Technical support hotline

- Regular maintenance workshops and webinars

Ensure all maintenance personnel are thoroughly trained on your specific solids control systems and follow all safety protocols.

Maintenance Record Keeping

Maintaining detailed records is crucial for tracking equipment health and planning maintenance activities. Record:

- Daily inspection results

- Lubrication activities

- Parts replacements

- Performance issues and resolutions

- Hours of operation

These records help identify patterns, predict failures, and justify equipment upgrades or overhauls.